Development of customized smart seedling cultivation

- Publication Date: 2019-12-23

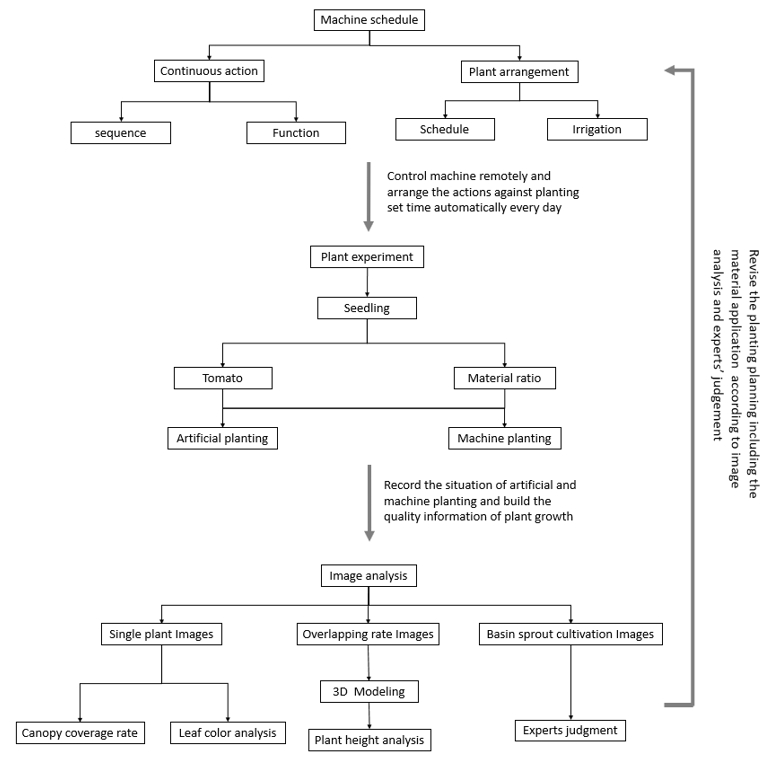

| Execution Methods |  The flow chart of Customizable intelligent seedling system. (1) Machine schedule: Automatically perform the specified irrigation operation which supplies quantitative water and fertilizer for plants or other custom schedules at the set time by using the web page of Farmbot to remotely control it. (2) Cultivation experience: Tomatoes with high economic value, strong growth potential and suitable for indoor environment cultivation were selected as experimental samples. They were cultivated in two ways, artificial and mechanical, for a total of two periods. 1. Moisture: The standard of irrigation is when the soil moisture content was less than 30% in a day of moisture detection. Water is artificially sprinkled with a sprinkler. The machine will give each 18ml of water, and adjust the water amount according to the soil conditions and the maturity of the seedlings that day or adjust the water flow pressure according to the size of the seedlings. 2. Fertilizer: The machine applies a 20ml amount of fertilizer to each at a frequency of 3 to 5 days when the cotyledons grow before leave growth, and watering will be stopped on the day of fertilization. (3) Image analysis: During the process of seedling raising, three types of image sampling were performed including the type of single plant, overlapping rate, and basin sprout cultivation shooting. Single plants and overlapping rate were taken daily, and the entire basin sprout cultivation was shot on the 21st day. The leaf color analysis was conducted by using the single plant shooting and 3D modeling was performed after overlapping rate shooting to analyze the plant height. Experts judge the health of the seed based on the images of the whole basin sprout cultivation, and the study use it as the basis for the image analysis of seedlings. |

| Performance Evaluation | Tomatoes with high economic value was appropriate to develop a small-area intelligent seedling system in cities. The system has the technical ability to perform automated cultivation and information control based on crop quality and planting specifications through robot arms to maximize agricultural output per unit. The robot arm actions were remotely controlled with the cloud, and can use the sensors to determine whether to implement irrigation or not, as well as accurate the irrigation volume for reducing labor problems. The growth status (such as leaf color, green coverage, and plant height) was monitored with images during the planting process. Random forest classification was used to identify the quality of the plants and the accuracy was 75.9% based on expert experience. In the future, it can be replicated in other crops to achieve multi-item applications, and implement different irrigations for different plant needs to improve the seedling rate and maximize the seedling growth benefits. |

| Conclusion & Suggestion | 1. Establish the machine seedling model of tomato, which can be replicated in others high-economic crops, to customize the seedling with the precise watering mode and save the labor cost. 2. Establish a modular schedule of Farmbot, which can be fine-tuned according to the previous planting results and increase the number of machine groups as needed. 3. Real-time monitoring of plant growth, accurate watering and fertilization, control of seedling quality, and shortening of seedling time. 4. The official cloud website service is currently used to control the machine. In the future, a local server can be used to build a machine control and the data analysis platform. |

| Appendix | Appendix 1 |